HAZOP is a Hazard and Operating problems study. A formal systematic rigorous examination to the process and engineering facts of a production facility. A qualitative technique based on “guide words” to help provoke thoughts about the way deviations from the intended operating conditions can lead to hazardous situations or operability problems. There are some standards and guidelines related to HAZOP like: IEC 61882, and OSHA (CFR Part 1910, 1992).

HAZOP have some objectives like: identify equipment and associated operator interfaces in the context of the complete system, and identify all deviations from the way a system is intended to function. HAZOP study purpose is emphasizing upon the operating integrity of a system, thereby leading methodically to most potential and detectable deviations which could conceivably arise in the course of normal operating routine.

OSHEQ Planet introduce 8 hours HAZOP Study Awareness course by distance learning, online instructor led, or one day classroom session. After completion the course you will be:

- Know the key principles and methodologies associated with executing a HAZOP study.

- Conduct the needed preparations for the HAZOP workshop as planning and preparations are key to success.

- Explain how to conduct a procedural HAZOP workshop.

- Prepare for a successful HAZOP study that clearly identifies scope and timeframes.

- Select and motivate the HAZOP team to complete the study on time and with results.

- Guide productive HAZOP study meetings to reach positive outcomes.

- Identify and solve problems that arise during HAZOP studies.

- Create effective and user-friendly HAZOP study reports.

- Analyze HAZOP study results and make organizational improvement recommendations.

- Identify the difference between HAZOP and CHAZOP.

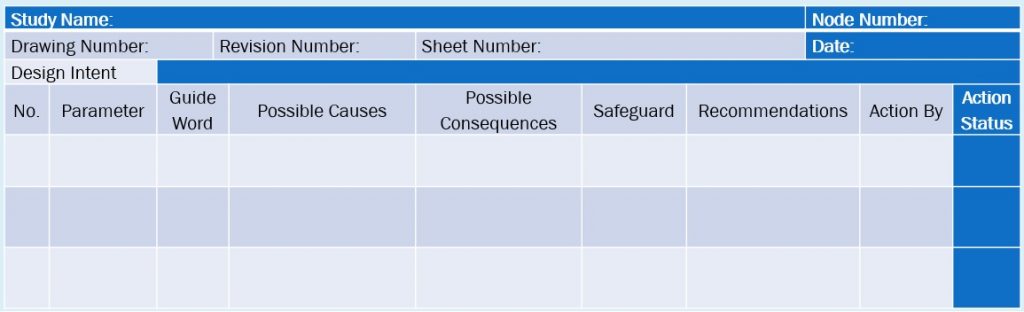

HAZOP study are three types: process, human, and procedures. Use some parameters like: Flow, Composition, pH, Pressure, Addition…etc.). There are some documents that used for the HAZOP Study like Process Flow Sheet or Process Flow Diagram (PFS or PFD), Piping and Instrumentation Diagram (P & ID), and layout. It used guidewords to identify causes and deviation of process. For instance, No Flow, More Temperature, or part of. The figure below is example of HAZOP study worksheet as reference.

HAZOP study are applied during:

- Normal operation.

- Foreseeable changes in operation, e.g., upgrading, reduced output, plant start-up and shut-down.

- Suitability of plant materials, equipment and instrumentation.

- Provision for failure of plant services, e. g. steam, electricity, and cooling water.

- Provision for maintenance.

HAZOP results can be used for Improvement of operations, Improvement of procedures, General awareness among involved parties, and Team building. The study will be managed by HAZOP study leader, and their team (secretary, Process Engineer, Instrument Engineer, chemist, etc.). Finally, a HAZOP study report will be generated with results, work sheets, diagrams, and methodology.

The student will receive a course completion certificate after pass the 15 multi choice exam, candidate should get 80% to pass the course, have 5 attempts to pass the course, and electronic certificate will be generated automatically. The course approved from the National Association of Safety Professionals (NASP) and the student can request international certificate approved worldwide. For more information about the course description, registration, and objectives just browse our website (www.osheqplanet.com).