The learner will able to: - Increase his knowledge about the structure of back and how it becomes injured. - Implement the back pain Risk Assessment. - Identify the common causes of Back Pain. - Identify the proper lifting procedures. - Improve the delegate skills to prevent the back pain. -

The learner will able to: • Understand the different OSHA regulations and requirements for machine guarding. • Understand the Key Parts of the Machine hazards. • Identify the importance of machine guarding. • Know the proper requirements of safeguards in machines. • Understand th

The learner will able to: • Understand OSHA history, objectives and effect to enhance the Safety and Health Management System in workplaces. • Identify the different types of OSHA Standard, Recordkeeping and Reporting. • Well know with the responsibilities of workers and employer under OSHA

After completion the course the learner will be able to: • Know the different standard in Arc Flash Protection (OSHA, NFPA and NEC). • Understand arc flash basics, causes and related hazards like burns. • Identify the Employer and employee Responsibilities. • Identify the methods to make

After completion the 4 hours course the learner will be able to: - Define what is asbestos and its history? - Describe where asbestos is found and types? - Explain associated health hazards. - Illustrate how to protect yourself and co-workers against asbestos hazards. - Clear understanding what

After completion the course the learner shall be able to: - Understand the meaning of noise, hearing loss, and some important & related definitions. - Describe the different types of noise hazards and effects. - Describe the different noise control measures and hierarchy of controls. - Unde

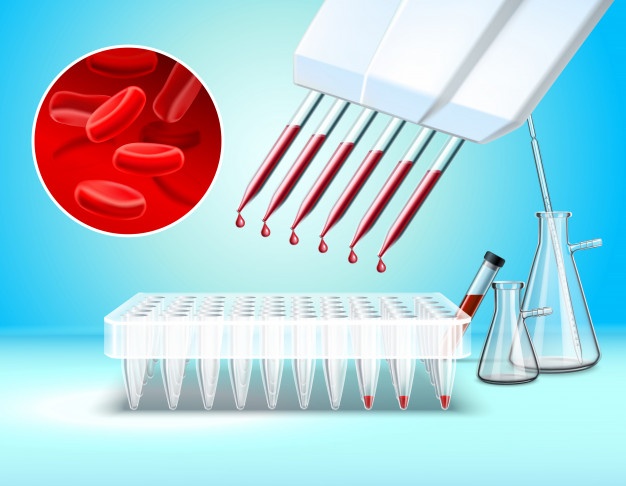

After completion the course the learner will be able to: - Comply with the OSHA Blood borne Pathogens Standard, 29 CFR 1910.1030. - Identify the different types of bloodborne pathogens, and how they cause infection. - Recognize potential exposure incidents. - How to work safely with body fluids

The learner will able to: • Identify the types of material handling equipment. • Describe Hazards associated with material handling activities. • Clarify the Prevention of hazards associated with material handling equipment. • Describe Employer requirements to protect workers from mate

After completion the course the learner will be able to: • Develop an understanding of violence and its impact on the workplace. • Develop policies in the workplace that address violence. • Develop employees’ awareness and skill in recognizing, responding to, and supporting employees who

After completion the course the learner will be able to: • Compliance with OSHA’s general industry standards (29 CFR 1910.22-28) in slips trips and falls. • Know the Costs of Slips, Trips, and Falls for employee and employer. • Identify the common conditions and dangers of slips, trips an

After completion the course the learner will be able to: • Familiar with the OSHA Standard for walking and working surfaces. • Familiar with some important definitions related to the walk and work surfaces (i.e. Floor hole, Floor opening…. etc.). • Increase his knowledge with the floor &a

The learner will able to: • Understand Human Behavior, Attitudes and Safety Culture. • Identify the main causes of unsafe behavior and acts. • Distinguish the difference between safety program and safety culture. • Create a proper safety culture and examine the progression. • Know th

The learner will able to: • Know the importance of egress in workplaces. • Understand the means of egress as per OSHA Standards for the general requirements and Employee emergency plans and fire prevention plans. • Understand the fire safety as per OSHA Standards with different aspects and

The learner will able to: • Understand the OSHA Electrical Safety regulations and requirements. • Identify the theory of electricity, types and exposure classification. • Raise the awareness to potential electrical hazards (Shock, Burns, Fall, Fires and Explosions). • Know how to recog

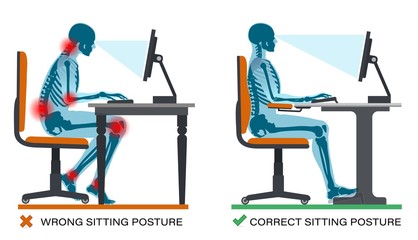

After completion the course the Learner will be able to: • Understand why the workplaces should have ergonomics process to protect workers. • Recognize the warning signs and symptoms of ergonomic injuries. • Know the Equipment that could be used to demonstrate how to avoid injuries when: Li

The learner will able to: • Understand the definition of H2S, its properties, hazards and effects on the human body. • Recognize the sources of human and environmental exposures. • Interpret the various H2S standards, requirements, and guidelines for application in the workplace. • Under

The learner will able to: • Define what is meant by Lock-Out Tag-Out and when it is used and not used. • Identify the importance and purpose of LOTO. • Understand the roles and responsibilities of those involved with LOTO. • Know the requirements of the OSHA LOTO regulations and where t

After completion the course the learner will be able to: • Recognize the costs of workplace accidents. • Recognize benefits of implementing an effective safety and health program. • Describe the elements of an effective safety and health program. • Identify three methods to prevent workp

After completion the course the learner will be able to: • Identify fall hazards and when fall protection is needed. • Identify methods of fall prevention as well as types of fall protection and their basic components (fall arrest, fall restrain, Anchor points, Full Body Harness and Lifeline).

The learner will able to: • Identify the OSHA Standard related to confined space entry and describe the entry flow chart. • Improve the delegate skills to identify the confined spaces, Characteristics and their classes. • The delegate will increase his knowledge to identify the 11 steps fo

After completion the course the learner will be able to: • Meet the OSHA Requirements in Hazard Communication and GHS. • Demonstrate an understanding of what constitutes a hazardous substance, their risks, classification and hazards associated with them. • Understand the Wr?tten Hazard Comm

• This course provides an introduction to the Incident Command System (ICS) and the first steps in Incident Command Management. • The course contains descriptions of the history and organizational structure of ICS, key features and principles. • It also contextualizes the relationship betwee

The learner will able to: • Identify the supervisor tools to identify & correct hazards using the hierarchy of controls. • How to investigate incident and accident with the proper process. • Identify the different types of safety training with the different designations. • What is le

After completion the 8 hours course the learner will be able to: - know the fundamental and chemistry of fires, and related OSHA Standards. - Identify fire hazards in the workplace and classification of fires. - Be aware of fire safety devices in their office and building. - Be familiar with the

The learner will able to: • Understand OSHA’s Compressed Gases-General Requirements (29 CFR 1910.101). • Understand the gas cylinders, compressed gases hazards and causes of incidents. • Well know the importance of identification and labeling and markings of gas cylinders. • The prope

The learner will able to: • Define the Crisis Management Elements and infrastructure. • Define core concepts of crisis communication planning, tools and media response. • Demonstrate the Stages of Crisis Management. • Identify the Role of Crisis Management Team. • Apply best practice

The learner will able to: • Identify types of Health Hazards in the workplace. • Describe strategies to control Chemical hazards. • Describe strategies to control Biological hazards. • Describe strategies to control Physical hazards. • Describe strategies to control Ergonomic hazard

The learner will able to: • Understand OSHA’s general requirements concerning welding, cutting and brazing. • Identify and understand the general safety requirements and general requirements for all types of welding. • Identify the specific safety requirements for oxygen-fuel gas welding

After completion the course the learner will be able to: • Familiarize with the regulations, responsibilities, and best practices as outlined in OSHA standard. • Provide an Introduction to Crane rigging Safety and lifting. • Provide Training as Required by OSHA. • Establish Crane and Sl

After completion the HAZID Study Awareness course the learner will be able to: • Enrich his knowledge about HAZID study Objectives, Types, guidewords, nodes, and Methodology and study recommendations reporting. • Familiar with the Theoretical and practical knowledge and skills to prepare and

The learner will able to: • Identify the OSHA Standard related to Personal Protective Equipment’s (PPE), employer & employee responsibilities to protect their workers from hazards. • Improve delegate’s skills to identify the proper and required PPE in the workplace. • Identify the

After completion the course the learner will be able to: • Identify the benefits specific to an organization in relation to implementing an effective OH&S MS. • Understand the terminology of OH&S management systems. • Understand and explain how the PDCA (Plan-Do-Check-Act) framework

After completion the course the learner will be able to: - Familiarize with the Regulations, Responsibilities, and best practices as outlined in OSHA standard. - Understand why the forklift safety is very important with some cases. - Understand how forklifts work and their attachment. - Know h

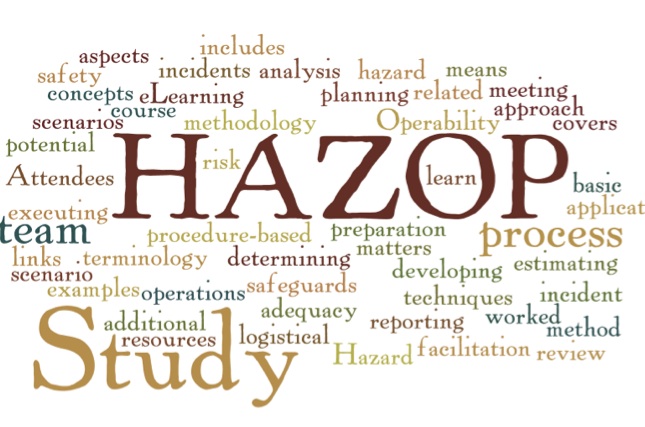

After completion the HAZOP Study Awareness course the learner will be able to: • Explain the key principles and methodologies associated with executing a HAZOP study. • Conduct the needed preparations for the HAZOP workshop as planning and preparations are key to success. • Explain how to c

Prepare personnel with the required technical knowledge and awareness to perform effectively in a supervisory position within a Hazardous Materials (HAZMAT) response team and also to meet the HAZWOPER Hazmat Technician competency level (29 CFR 1910.120) including all aspects and fundamentals.

The purpose of this course is to train employees in how to safely transport dangerous materials. This is accomplished by setting standards and regulations on how the materials are packaged, setting up a system of labeling hazardous materials and designing guidelines on how the materials move from on

After completion the course the learner will be able to: • Identify the OSHA Laboratory Standard and Requirements. • Familiar with the different laboratory hazards (Physical, Chemical, and Health…. etc.), the needs to minimize the exposure, and preventing accidents and injuries in the lab en

• The 10-hours General Industry Course is intended to provide entry level general industry workers information about their rights, employer responsibilities, and how to file a complaint as well as how to identify, abate, avoid and prevent job related hazards on a job site. • The training cover

.jpg)

• This 10-hours training program is intended to provide entry level construction workers information about their rights, employer responsibilities, and how to file a complaint as well as how to identify, abate, avoid and prevent job related hazards on a construction site. • The training covers

• The 30-hours Construction Safety and Health Program is intended to provide workers with some safety responsibility a greater depth and variety of training on an expanded list of topics associated with workplace hazards in construction industry. • The Program provides training for workers and

• The 30-hour General Industry Course is intended to provide a variety of training to workers with some safety responsibility. • Training should emphasize hazard identification, avoidance, control and prevention, as well as OSHA standards. • The program also provides information regarding w