INTRODUCTION:

Over 7700 people die each day form work – related accidents or diseases – that’s nearly 2.78 million every year. In addition, every 15 seconds, a worker dies from a work – related accident or disease, and 153 people experience a work – related injury. ISO 45001:2018 is a new international standard which provides a framework, regardless of size, activity and geographical location, to manage and continuously improve Occupational Health and Safety (OH&S) within the organization. ISO 45001:2018 is an ISO standard and has been designed to have greater compatibility with existing ISO standard management system revisions including ISO 9001:2015 and ISO 14001:2015.

The standard promotes worker participation when identifying hazards, elimination or reducing risk by implementation of controls integrated with other business process. This approach can improve safety culture, minimize risk and embed best practice resulting in increased productivity. Implementation is also recognition for having achieved an international standard benchmark which may have positive influence on existing and potential customers in fulfilling their own social responsibility commitments.

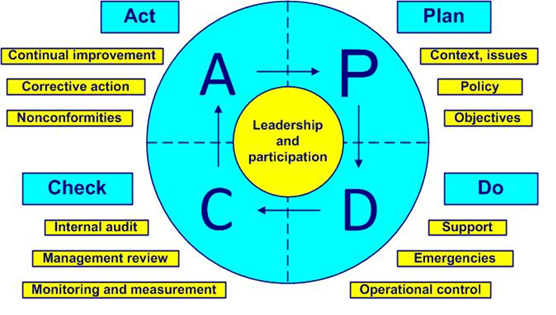

PDCA Cycle:

PLAN: Understand the context of the organization including OH&S risk and opportunities. Establish OH&S objectives, processes and resources required to deliver results in accordance with the organizations OH&S Policy.

DO: Implement the processes as planned to including worker participation, hazard identification and emergency preparedness.

CHECK: Monitor, measure and evaluate OH&S activities and processes.

ACT: Take actions to continually improve to including findings of incidents, addressing non-conformance and audit findings.

Risk Based Thinking (RBT):

Is a central tenet of ISO 45001. RBT requires the Management Team to continually assess the issues that affect OH&S aspects of an organization and ensure that appropriate targets, resources and controls are in place. RBT empowers organizations to make dynamic changes to their objectives and focus, whilst at the same time ensuring that resources are in place to control changes and unforeseen circumstances. In relation to OH&S, risk-based thinking extends to areas outside of the organization which may influence safety.

After completion the course the learner will be able to:

- Identify the benefits specific to an organization in relation to implementing an effective Occupational Health & Safety Management System (OSHMS).

- Understand the terminology of OHSMS.

- Understand and explain how the PDCA (Plan-Do-Check-Act) framework relates to the process approach promoted in ISO 45001:2018.

- Explore the intent and interpretation of the individual clauses of ISO 45001 OHSMS and define each Clause-by-Clause elaboration of complete standard.

- Gain a basic understanding of how an OHSMS can be integrated into existing quality management systems.

- Interpret key concepts and requirements of ISO 45001 from an implementation perspective.

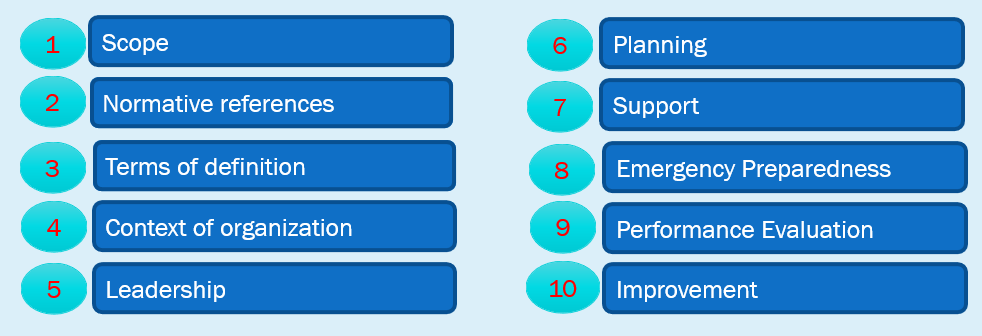

ANNEX SL:

It’s a high-Level Structure, consists of 10 core clauses that manage the OSHMS.

CONCLUSION:

To have effective ISO System, the organization should consider it implementation not only documentation. Any company that operates an OH&S Management System must ensure there are effective measures to evaluate performance which enables continual improvement internally. This course recommended for all health and safety professionals, and anyone involved in the planning, implementing, maintaining, supervising or auditing of an OSHMS. This is 8 hours course or 2 days classroom. No special requirements or recommendations as Prerequisites. The course certificate is internationally recognized worldwide. To register with the course or read more, visit our site (www.osheqplanet.com).

Great content! Keep up the good work!

Thank you linda.watson@gmail.com for your feedback. keep your self updated with our site.

Thanks for your blog, nice to read. Do not stop.

Thank you mailaselflat1987@gmail.com for your feedback. keep your self updated with our site.